Bentley Blower Builds Begin

Last year, we brought you news of the new Bentley Blower Continuation cars. Now, in a bespoke Bentley Mulliner workshop, the project is coming together. But this is still a learning and development moment for Bentley, which is now a pioneer with this, the first pre-war continuation project of its kind. Why? Because the car being built right now is ‘Car Zero’. This is the car that will prove the validity and detail of Bentley’s development work.

To get to this point, with ‘Car Zero’, the team at Bentley first had to completely disassemble car #2 – an original car from period, and possibly the most valuable Bentley in existence. To take apart such a car is a job in and of itself. But that wasn’t the end of the story. Bentley engineers then had to scan, map and digitally recreate every part. From this information, the parts could be remade for the continuation cars. Impressive, highly technical stuff. And yes, they did put #2 back together, worry not.

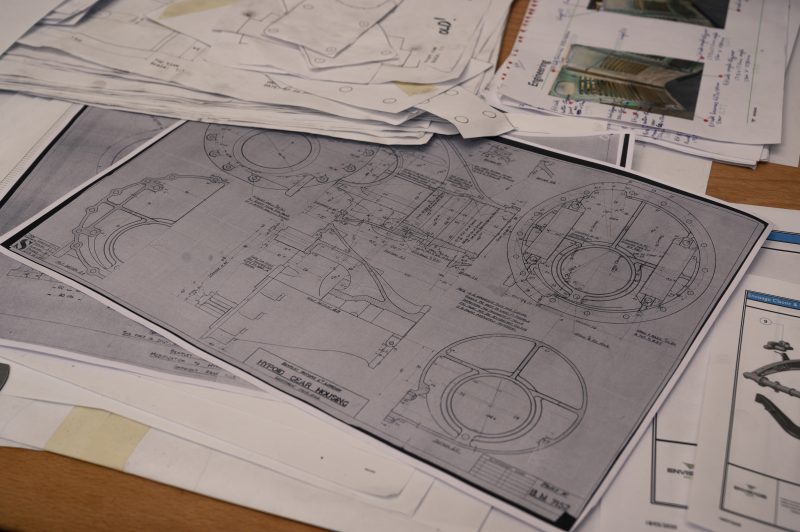

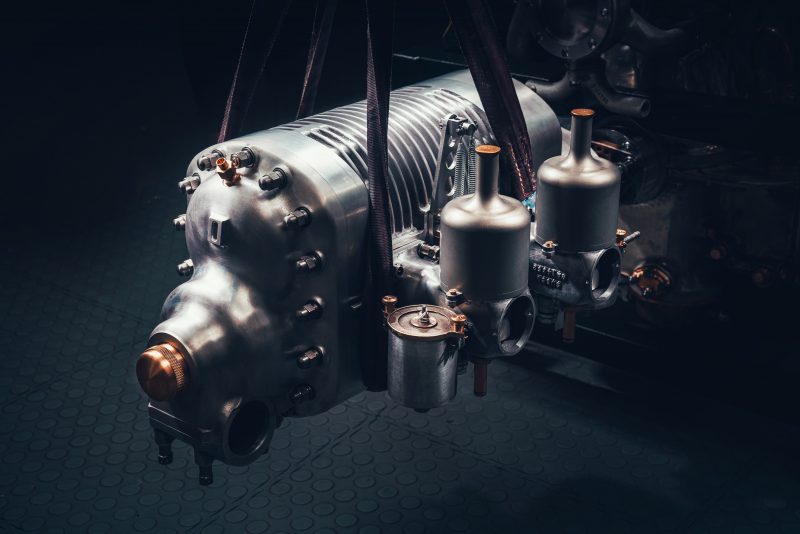

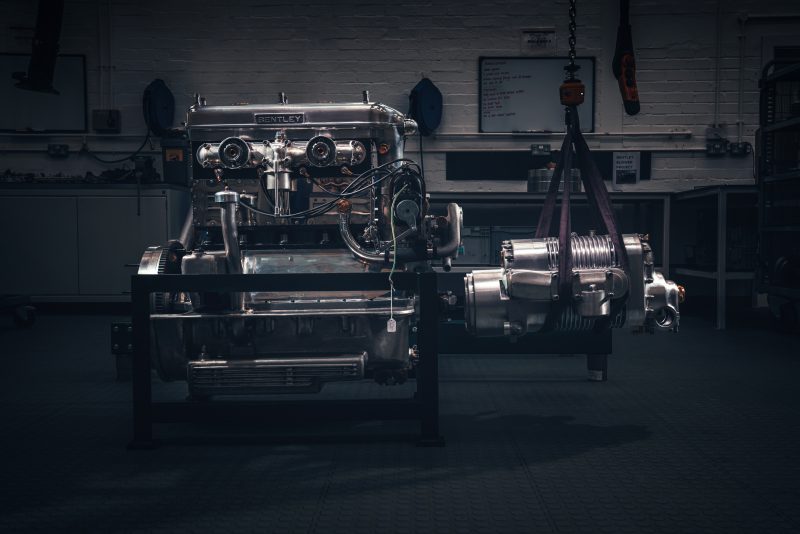

And that brings us to ‘Car Zero’. The chassis, to which almost everything will be affixed, was first to arrive. Then the fuel tank and radiator were next, as work was completed on the ash frame for the body. The first pair of headlights was delivered, while the mechanical aspects of the first car started to come together – the very first engine (complete with remade Amherst Villiers supercharger), the front axle assembly and the leaf springs. This coming together of parts is the result of cutting edge CAD and laser scanning technology, paired with traditional drawings from period. This car will be the model used for a future, more involved development programme.

Speaking about the project, Bentley Mulliner’s Tim Hanning said; “After almost a year of highly detailed engineering work, it is extremely rewarding to see the first parts coming together to form the first Bentley Blower in over 90 years. The skill of our engineers and technicians in completing hundreds of individual part specifications is equalled only by that of the artisans across the country that have handmade the components that we’re now starting to bolt together. As we go, we’re refining designs and fixing problems, which is exactly what a prototype build is for. We’re all really excited to get this first car finished, and to show it to the world later this year.”

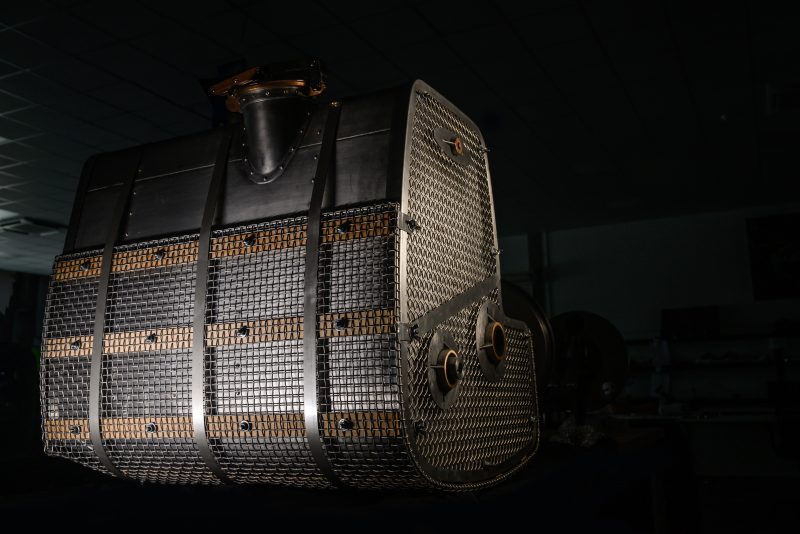

The chassis has been created in heavy-gauge steel, hand-formed and hot riveted by the specialists at Israel Newton & Sons Ltd. This 200-year old company traditionally makes boilers for steam locomotives and traction engines, and as such has the skills to forge and shape metal in a traditional way.

The Vintage Car Radiator Company, based at Bicester Heritage, has crafted exact recreations of some of the Blower’s key components – including the mirror-polished, nickel-plated radiator shell and the hand-beaten fuel tank formed in steel and copper. Market leaders in the manufacture and restoration of vintage car radiators and components to the highest possible standards of craftsmanship and authenticity, they were the perfect choice to handcraft these tricky and vital components.

These parts will feed the first Blower’s brand new 4½-litre engine, originally designed by W.O Bentley himself and now recreated by Bentley Mulliner with the expert support of specialists including NDR Ltd. Featuring many innovations of which a sports car engine of the 1970s would be proud – aluminium pistons, an overhead camshaft, four valves per cylinder and twin spark ignition – the renowned 4½-litre engine will meet a newly machined, exact recreation of an Amherst Villiers roots-type supercharger. Mulliner’s experts will then be tuning the engine on a specially-prepared testbed at the Bentley factory in Crewe, where together the engine and supercharger should generate around 240 bhp.

It is a spectacular project, but one that relies heavily on the successful development of ‘Car Zero’. But given this is Bentley we’re talking about, there is little cause for concern. This first car, apart from being a testbed, will also be shown to the twelve lucky customers who have already secured the Continuation cars. After this, sometime in autumn, ‘Car Zero’ will be unveiled completely. A new car, but a vintage one. Built with the same passion and spirit as those original cars, but with the helping hand of modern, cutting-edge technology and manufacturing principles. This car and the wider project is, quite simply, incredible.